Product Description

Product Description

Certificate

Features

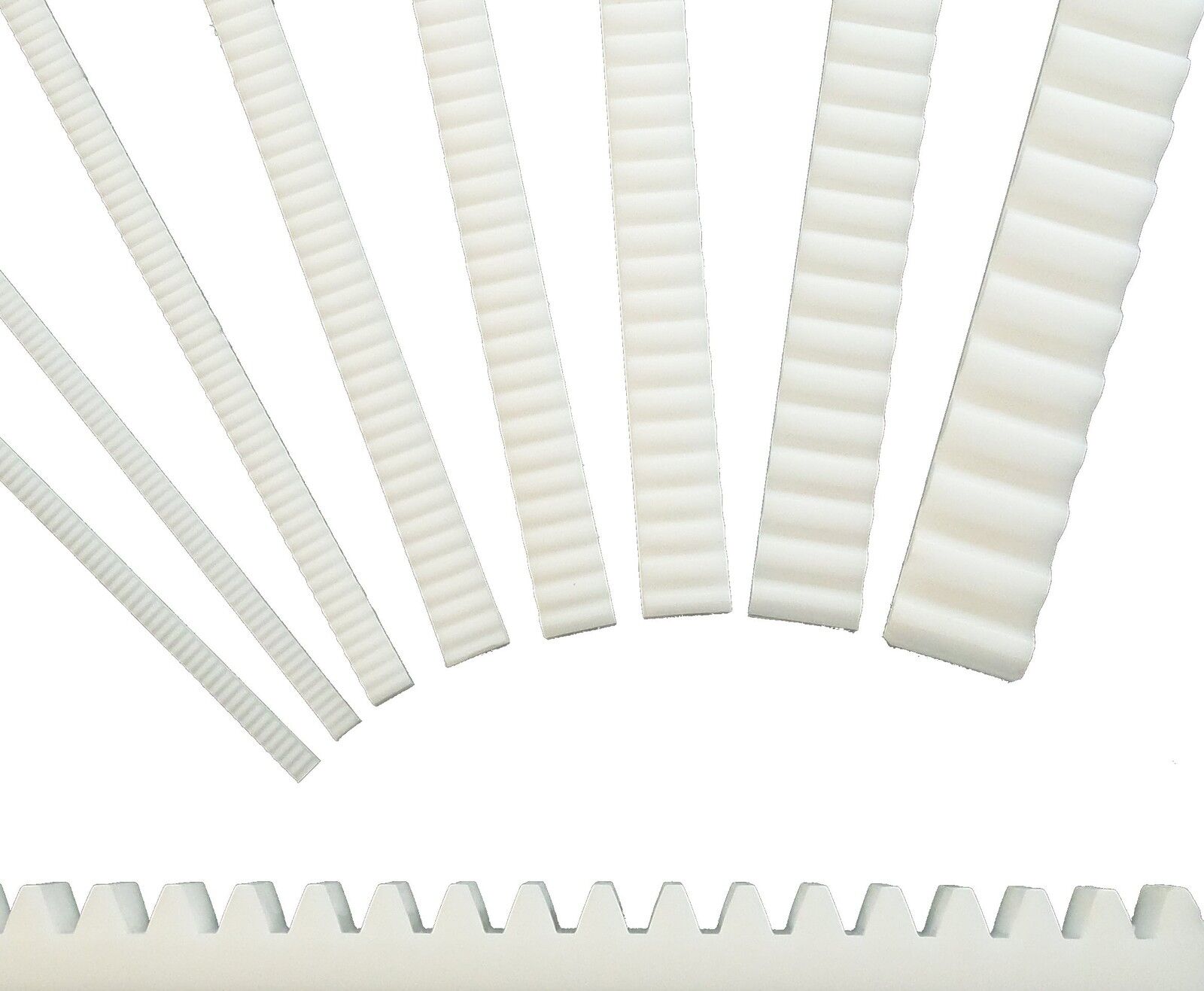

1. Available in sizes in Module1.5/2/3/4/5/6/7/8/9/10

2. Repeatability of up to ± 0.01mm

3. Powerful rack and pinion drives for reliable movements.

4. Extremely compact frame with high inherent stiffness

5. It is designed for high-temperature resistance, long service life.

6. Rigidness improved, Smaller size, Easy to maintain, Improve accuracy, Easy assemble, etc.

Maintenance

1. Lubricate the product before the initial use. Note the type of grease used and avoid mixing different types together.

2. For normal operating conditions, it is recommended to check the operation every 100km, clean and supply grease CHINAMFG the rack and pinion.

| Brand | TOCO |

| Model | Rack and pinion |

| Size customize | Module1.5/2/3/4/5/6/7/8/9/10 |

| HS-CODE | 8483900090 |

| Items packing | Plastic bag+Cartons Or Wooden Packing |

| Payment terms | T/T, Western Union |

| Production lead time | 15 business days for sample, 35 days for the bulk |

| Keyword | Rack and pinion |

| Application | 1. Automatic controlling machine 2. Semi-conductor industry 3. General industry machinery 4. Medical equipment 5. Solar energy equipment 6. Machine tool 7. Parking system 8. High-speed rail and aviation transportation equipment, etc. |

Catalogs

ZheJiang brand registered trademark, High-Tech Enterprise, letter patents, and ISO.

CHINAMFG Group is a professional manufacturer of transmission components in China, mastering key technologies and focusing on innovative research and design. CHINAMFG Group has multiple product design patents and through the ISO9001 certification and national high-tech enterprise certification.

CHINAMFG has a complete product line, including Mono Stage, Linear Module, Linear Xihu (West Lake) Dis., Ball Screw, Support Unit, Rack and Pinion.

You may find more information on our website at www.toco.tw.

Any questions, pls feel free to contact us.

We mainly produce Mono Stage, Linear Module, Linear Xihu (West Lake) Dis., Ball Screw, Support Unit, Rack and Pinion.

FAQ :

1. Service :

a. Help customers to choose the correct model, with CAD & PDF drawing for your reference.

b. Professional sales team, make your purchase smooth.

2.payment :

Sample order: We require 100% T/T in advance. sample express need request pay by clients

Bulk order: 30% T/T in advance, balance by T/T against copy of B/L.T/T, Paypal, Western Union is

acceptable.

3.Delivery :

sample: 5-10 business days after payment confirmed.

Bulk order:10-20 workdays after deposit received.

4. Guarantee Time

TOCO provides a one-year quality guarantee for the products from your purchase date, except for

the artificial damage.

5.After sale-Service

During the warranty period, any quality problem of the CHINAMFG product, once confirmed, we will

send a new 1 to replace.

| Application: | Machinery, CNC Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Straight/Helical |

| Material: | Stainless Steel |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can rack and pinion mechanisms be customized for specific machinery and equipment?

Yes, rack and pinion mechanisms can be customized to suit specific machinery and equipment requirements. Here’s a detailed explanation of how rack and pinion systems can be customized:

- Size and Dimensions: Rack and pinion systems can be customized in terms of their size and dimensions to fit the available space and integration requirements of the machinery or equipment. The length, width, and height of the rack can be adjusted, and the pinion gear size can be modified to ensure proper fit and compatibility.

- Materials: The choice of materials for the rack and pinion components can be customized based on factors such as load capacity, environmental conditions, and specific application requirements. Different materials, such as steel, stainless steel, aluminum, or various alloys, can be selected to optimize strength, durability, corrosion resistance, and other desired properties.

- Teeth Profile: The tooth profile of the rack and pinion gears can be customized to meet specific application needs. Different tooth profiles, such as straight, helical, or even custom-designed profiles, can be utilized to enhance load distribution, reduce noise, increase contact area, or improve efficiency based on the unique requirements of the machinery or equipment.

- Precision and Tolerance: The precision and tolerance levels of rack and pinion systems can be customized to achieve the desired level of accuracy and motion control. Tighter tolerances can be specified to enhance positioning and repeatability, while looser tolerances may be suitable for applications that prioritize cost-effectiveness over extreme precision.

- Mounting Options: Rack and pinion systems can be customized to offer various mounting options to facilitate integration with specific machinery or equipment. Mounting holes, brackets, or specific attachment mechanisms can be incorporated into the design to ensure proper alignment, stability, and ease of installation.

- Accessories and Features: Customized rack and pinion systems can include additional accessories or features to enhance functionality and application-specific requirements. This can include the incorporation of sensors, limit switches, lubrication systems, protective covers, or any other components that are necessary for the proper operation and maintenance of the machinery or equipment.

- Integration with Control Systems: Rack and pinion systems can be customized to integrate seamlessly with the control systems of the machinery or equipment. This allows for synchronization, feedback control, and coordination with other system components, enabling precise motion control and automation in line with specific application needs.

By considering factors such as size, dimensions, materials, tooth profile, precision, mounting options, accessories, and integration with control systems, rack and pinion mechanisms can be effectively customized to meet the unique requirements of different machinery and equipment. Customization ensures optimal performance, reliability, and compatibility, allowing rack and pinion systems to be tailored for specific applications across various industries.

Can rack and pinion systems be used in the automotive industry, and if so, where?

Yes, rack and pinion systems are widely used in the automotive industry for various applications that require precise motion control. Here’s a detailed explanation of how rack and pinion systems are employed in the automotive industry:

Rack and pinion systems offer several advantages that make them suitable for automotive applications:

- Steering Systems: One of the primary applications of rack and pinion systems in the automotive industry is in steering systems. Rack and pinion steering systems provide a direct and efficient method for converting rotational motion into linear motion, allowing the driver to control the direction of the vehicle. In this setup, the pinion is connected to the steering shaft, while the rack is attached to the front wheels. As the driver turns the steering wheel, the pinion rotates, causing the rack to move laterally and steer the wheels. Rack and pinion steering systems are commonly used in passenger cars, light trucks, and SUVs due to their compact design, precise control, and responsive handling characteristics.

- Power Steering: Rack and pinion systems are also utilized in power steering systems to enhance the ease of steering for the driver. In power steering setups, hydraulic or electric assist mechanisms are incorporated into the rack and pinion system to reduce the effort required to turn the steering wheel. These mechanisms provide additional force or torque to assist the driver, making steering more comfortable and responsive. Power steering systems based on rack and pinion mechanisms are prevalent in modern vehicles, offering improved maneuverability and control.

- Transmission Shifters: Rack and pinion systems can be employed in transmission shifters to facilitate gear shifting in manual or automated manual transmissions. The rack and pinion mechanism translates the linear movement of the gear shifter lever into rotational movement to engage different gears. This allows the driver to select the desired gear position for efficient power delivery and vehicle performance. Rack and pinion transmission shifters offer precise and reliable gear selection, contributing to smooth shifting and improved drivability.

- Convertible Top Mechanisms: In convertible vehicles, rack and pinion systems can be utilized in the mechanisms responsible for raising or lowering the convertible top. The rack is typically integrated into the folding framework, while the pinion is driven by an electric motor or hydraulic actuator. By rotating the pinion, the rack moves linearly, causing the convertible top to be raised or lowered. Rack and pinion convertible top mechanisms provide controlled and synchronized movement, allowing for convenient and efficient operation of the convertible roof.

- Other Applications: Rack and pinion systems find additional applications in the automotive industry, such as throttle control mechanisms, suspension systems, seat adjustments, and sunroof mechanisms. These systems utilize rack and pinion mechanisms to achieve precise and reliable control over various functions in the vehicle, enhancing comfort, convenience, and overall performance.

In summary, rack and pinion systems are extensively used in the automotive industry for steering systems, power steering, transmission shifters, convertible top mechanisms, and various other applications. Their ability to provide precise motion control, compact design, responsiveness, and reliability makes them a preferred choice in automotive engineering, contributing to improved safety, comfort, and driving experience.

Can you explain the typical applications of rack and pinion systems?

Rack and pinion systems find a wide range of applications in various industries due to their versatility, efficiency, and precise motion control. Here’s a detailed explanation of some typical applications:

- Automotive Steering: One of the most common applications of rack and pinion systems is in automotive steering mechanisms. In this application, the rack is connected to the steering column, and the pinion gear is driven by the steering input from the driver. As the pinion gear rotates, it moves the rack linearly, which in turn controls the movement of the vehicle’s front wheels, allowing for smooth and responsive steering.

- Robotics: Rack and pinion systems are widely used in robotics for precise and controlled linear motion. They can be found in various robotic applications, including robotic arms, gantry systems, pick-and-place robots, and CNC machines. The rack and pinion mechanism enables accurate positioning, fast movement, and high repeatability, making it ideal for tasks that require precise manipulation and motion control.

- Linear Actuators: Rack and pinion systems are commonly employed in linear actuators, which are devices used to convert rotational motion into linear motion. The pinion gear is driven by an electric or hydraulic motor, and the linear motion of the rack is utilized to extend or retract the actuator. Linear actuators based on rack and pinion systems are used in various applications, such as industrial automation, medical equipment, and aerospace systems.

- Machinery: Rack and pinion systems are utilized in a wide range of machinery and equipment. They are often employed in applications requiring precise linear motion control, such as cutting machines, printing presses, packaging equipment, and material handling systems. The rack and pinion mechanism enables efficient power transmission, accurate positioning, and quick response, enhancing the performance and productivity of the machinery.

- Automation: Rack and pinion systems play a crucial role in automation processes. They are used in automated systems for tasks such as part positioning, assembly, sorting, and conveyor systems. The precise and reliable linear motion provided by rack and pinion systems contributes to the efficiency and accuracy of automated processes.

In addition to the above applications, rack and pinion systems can be found in various other fields, including agriculture, construction, entertainment industry, and more. Their compact design, high precision, efficiency, and versatility make them a popular choice for converting rotational motion into linear motion in a wide range of mechanical systems.

editor by CX 2023-10-21