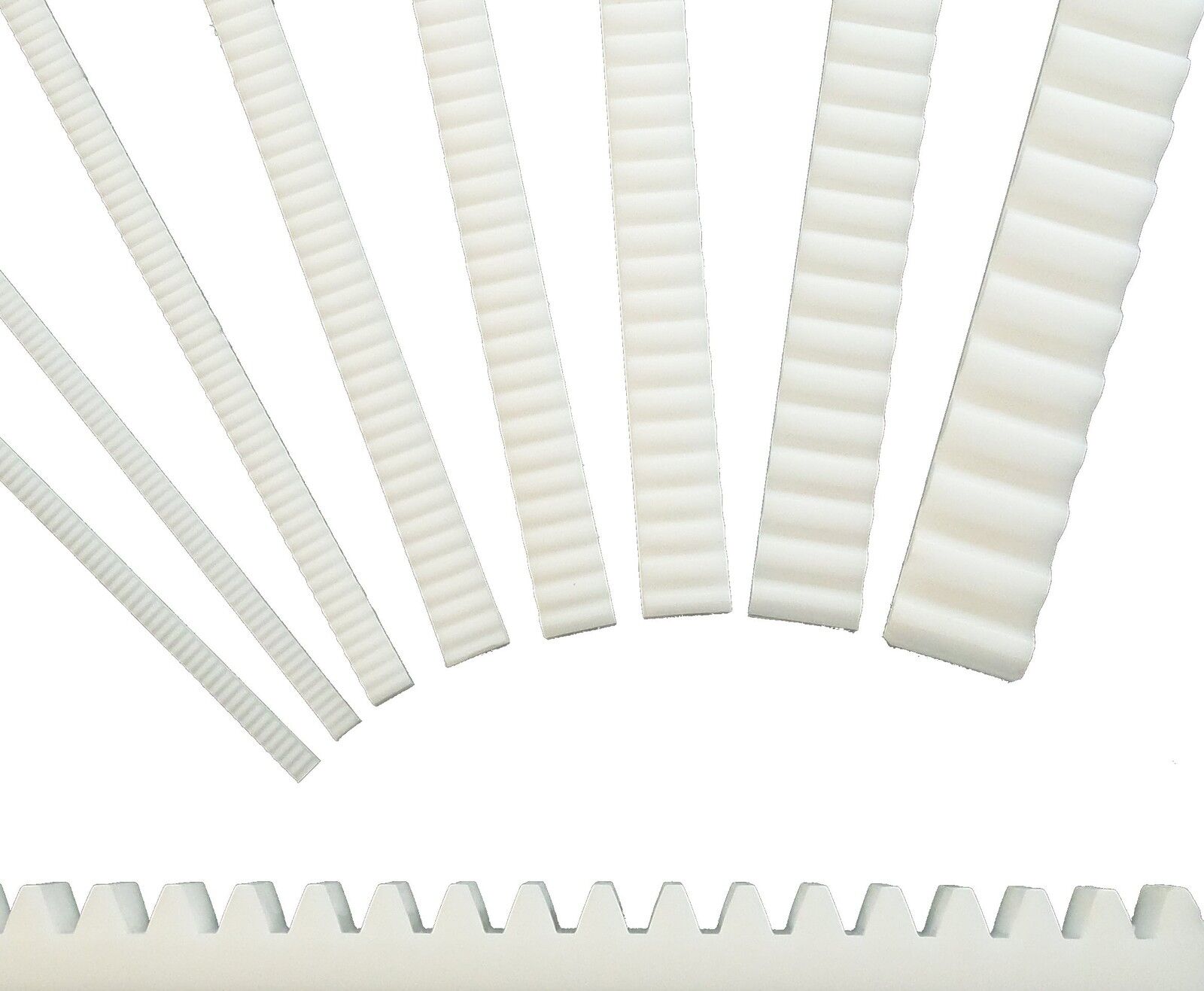

Product Description

| Product Name | Steering Rack |

| OEM No. | 53601-S9V-A01 26-2719 |

| Car Model | for Honda Pilot 2003-08 |

| MOQ | 1PC if we have stock, 50Pcs for production. |

| Delivery Time | 7-35 Days |

| Warranty | 12 Months |

| Package | Neutral White Box + Brown Cartons Packing 1 Pc/BOX |

| Our Advantage | 1. The same length as original one. 2. Lower MOQ is acceptable with more models. 3. Fast delivery. 4. Laser Mark for free. 5. Pallet with Film for free. |

Quality Control

Company Profile

Packing&Shipping

Certifications

Exhibition&Customers

Pay

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Yes |

|---|---|

| Warranty: | 12 Months |

| Type: | Steering Gears/Shaft |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do rack and pinion systems handle different gear ratios?

Rack and pinion systems are capable of accommodating different gear ratios to achieve specific mechanical advantages and motion characteristics. Here’s a detailed explanation of how rack and pinion systems handle different gear ratios:

In a rack and pinion system, the gear ratio is determined by the number of teeth on the pinion gear and the length of the rack. The gear ratio defines the relationship between the rotational motion of the pinion and the linear motion of the rack. Different gear ratios can be achieved through various design considerations:

- Number of Teeth: The number of teeth on the pinion gear directly affects the gear ratio. A larger number of teeth on the pinion gear compared to the number of rack teeth results in a higher gear ratio, providing increased mechanical advantage and slower linear motion of the rack per revolution of the pinion. Conversely, a smaller number of pinion teeth relative to the rack teeth yields a lower gear ratio, delivering higher linear speed but reduced mechanical advantage.

- Pitch Diameter: The pitch diameter of the pinion gear, which is the diameter of the imaginary circle formed by the gear teeth, also influences the gear ratio. Increasing the pitch diameter of the pinion relative to the rack diameter leads to a higher gear ratio, while decreasing the pitch diameter results in a lower gear ratio. By adjusting the pitch diameters of the pinion and rack, different gear ratios can be achieved.

- Module or Diametral Pitch: The module (for metric systems) or diametral pitch (for inch systems) is a parameter that defines the size and spacing of the teeth on the gear. By selecting different module or diametral pitch values, the gear ratio can be adjusted. A larger module or lower diametral pitch leads to a lower gear ratio, while a smaller module or higher diametral pitch results in a higher gear ratio.

- Multiple Stages: Rack and pinion systems can also incorporate multiple stages of gears to achieve complex gear ratios. By combining multiple pinion gears and racks, each with different tooth counts, gear ratios can be multiplied or divided to achieve the desired overall gear ratio. This approach allows for more flexibility in achieving specific motion requirements and torque transmission characteristics.

When selecting the appropriate gear ratio for a rack and pinion system, several factors should be considered, such as the desired linear speed, torque requirements, precision, and system constraints. Higher gear ratios provide increased mechanical advantage and torque multiplication, which is advantageous for applications requiring heavy loads or precise motion control. Lower gear ratios, on the other hand, offer higher linear speed and reduced mechanical advantage, suitable for applications that prioritize rapid movements.

It’s important to note that changing the gear ratio in a rack and pinion system may impact other performance aspects, such as backlash, load distribution, and system efficiency. Proper design considerations, tooth profile selection, and material choices should be made to ensure optimal performance and reliability while maintaining the desired gear ratio.

How do rack and pinion systems contribute to efficient power transmission?

Rack and pinion systems play a significant role in facilitating efficient power transmission in various mechanical applications. Here’s a detailed explanation of how rack and pinion systems contribute to efficient power transmission:

Rack and pinion systems offer several advantages that contribute to efficient power transmission:

- Direct Power Transfer: Rack and pinion systems provide a direct and efficient means of power transmission. The teeth of the pinion gear mesh with the teeth of the rack, creating a positive engagement. This direct contact allows for minimal power loss during transmission, as there are no intermediate mechanisms or components to introduce friction or slip.

- High Mechanical Efficiency: Rack and pinion systems are designed to have high mechanical efficiency, meaning they maximize the output power compared to the input power. The teeth of the pinion and the rack are carefully designed and machined to minimize friction and ensure smooth motion. This efficient transfer of power reduces energy waste and enhances overall system performance.

- Low Backlash: Backlash refers to the play or clearance between the teeth of the pinion and the rack. Rack and pinion systems can be designed with minimal backlash, which contributes to efficient power transmission. Low backlash ensures precise and immediate response to input motion, minimizing energy losses associated with tooth clearance and backlash compensation.

- Efficient Torque Transmission: Rack and pinion systems are capable of transmitting high torque efficiently. The engagement of the pinion teeth with the rack teeth distributes the applied torque evenly along the contact area, resulting in efficient torque transmission without slippage or power dissipation. This characteristic makes rack and pinion systems suitable for applications that require high torque output.

- Compact Design: Rack and pinion systems offer a compact design compared to other power transmission mechanisms. The linear nature of the rack allows for a more straightforward integration into space-limited applications. This compact design minimizes energy losses due to unnecessary mechanical components or complex transmission paths, resulting in more efficient power transmission.

- High-Speed Capability: Rack and pinion systems are capable of efficient power transmission at high speeds. The direct contact between the teeth of the pinion and the rack enables rapid and precise motion transfer without significant energy losses. This characteristic is advantageous in applications that require quick and accurate movements.

By combining features such as direct power transfer, high mechanical efficiency, low backlash, efficient torque transmission, compact design, and high-speed capability, rack and pinion systems contribute to efficient power transmission in a wide range of applications. These systems are commonly used in industries such as automotive, robotics, machinery, and aerospace, where efficient power transfer is crucial for optimal performance and energy savings.

Can you explain the typical applications of rack and pinion systems?

Rack and pinion systems find a wide range of applications in various industries due to their versatility, efficiency, and precise motion control. Here’s a detailed explanation of some typical applications:

- Automotive Steering: One of the most common applications of rack and pinion systems is in automotive steering mechanisms. In this application, the rack is connected to the steering column, and the pinion gear is driven by the steering input from the driver. As the pinion gear rotates, it moves the rack linearly, which in turn controls the movement of the vehicle’s front wheels, allowing for smooth and responsive steering.

- Robotics: Rack and pinion systems are widely used in robotics for precise and controlled linear motion. They can be found in various robotic applications, including robotic arms, gantry systems, pick-and-place robots, and CNC machines. The rack and pinion mechanism enables accurate positioning, fast movement, and high repeatability, making it ideal for tasks that require precise manipulation and motion control.

- Linear Actuators: Rack and pinion systems are commonly employed in linear actuators, which are devices used to convert rotational motion into linear motion. The pinion gear is driven by an electric or hydraulic motor, and the linear motion of the rack is utilized to extend or retract the actuator. Linear actuators based on rack and pinion systems are used in various applications, such as industrial automation, medical equipment, and aerospace systems.

- Machinery: Rack and pinion systems are utilized in a wide range of machinery and equipment. They are often employed in applications requiring precise linear motion control, such as cutting machines, printing presses, packaging equipment, and material handling systems. The rack and pinion mechanism enables efficient power transmission, accurate positioning, and quick response, enhancing the performance and productivity of the machinery.

- Automation: Rack and pinion systems play a crucial role in automation processes. They are used in automated systems for tasks such as part positioning, assembly, sorting, and conveyor systems. The precise and reliable linear motion provided by rack and pinion systems contributes to the efficiency and accuracy of automated processes.

In addition to the above applications, rack and pinion systems can be found in various other fields, including agriculture, construction, entertainment industry, and more. Their compact design, high precision, efficiency, and versatility make them a popular choice for converting rotational motion into linear motion in a wide range of mechanical systems.

editor by Dream 2024-05-03